Steel, the backbone of modern construction, offers unparalleled strength and versatility. From towering skyscrapers to sprawling industrial complexes, its robust nature allows for designs that push the boundaries of architectural possibility. However, steel’s Achilles’ heel lies in its vulnerability to high temperatures. In the event of a fire, unprotected steel can rapidly lose its structural integrity, leading to catastrophic collapses. This is where fire protection coatings step in, acting as a crucial line of defense. But what exactly are these coatings, and how do they work their magic? Let’s delve deep into the world of fire protection for steel structures.

Understanding the Threat: Steel and Fire

Steel, though strong, undergoes significant changes when exposed to extreme heat. As temperatures rise above 550∘C (1022∘F), steel begins to lose its yield strength, leading to deformation and eventual failure. This critical temperature is often reached within minutes of a fire’s outbreak, making unprotected steel a major hazard. The collapse of structural steel can trigger a chain reaction, bringing down entire buildings and endangering lives. Therefore, fire protection isn’t merely a regulatory requirement; it’s a fundamental safety imperative.

The Magic of Fire Protection Coatings: A Barrier Against Inferno

Fire protection coatings, also known as intumescent coatings, are specially formulated materials applied to steel surfaces to delay the onset of critical temperature. These coatings react to heat through a process called intumescence, expanding significantly to form a thick, insulating char layer. This char acts as a thermal barrier, slowing down the heat transfer to the steel substrate and maintaining its structural integrity for a predetermined period.

Types of Fire Protection Coatings: A Spectrum of Solutions

The market offers a range of fire protection coatings, each tailored to specific applications and fire resistance requirements. The most common types include:

- Epoxy-based Intumescent Coatings: These coatings are widely used for structural steel in both interior and exterior environments. They offer excellent durability, chemical resistance, and adhesion to steel surfaces. Epoxy-based coatings are available in various thicknesses to achieve different fire resistance ratings, typically ranging from 30 to 120 minutes.

- Water-based Intumescent Coatings: Environmentally friendly and low in volatile organic compounds (VOCs), water-based coatings are gaining popularity for interior applications. They provide good fire protection and are relatively easy to apply. However, they may require careful surface preparation and are generally less resistant to harsh environments compared to epoxy-based coatings.

- Cementitious Coatings: These coatings, typically composed of lightweight cement and aggregates, offer robust fire protection for structural steel and concrete. They are often used in industrial settings and areas requiring high fire resistance ratings, such as tunnels and power plants. Cementitious coatings are applied in thicker layers than intumescent coatings and provide excellent thermal insulation.

- Vermiculite-based Coatings: This type of coating utilizes vermiculite, a naturally occurring mineral that expands when heated, to create an insulating barrier. They are typically used for spray-applied fireproofing and offer good fire resistance for various steel structures.

The Intumescence Mechanism: A Chemical Symphony

The intumescence process is a complex chemical reaction triggered by heat. A typical intumescent coating comprises several key ingredients:

- Binder: The binder, usually a resin, provides adhesion to the steel substrate and forms the coating’s matrix.

- Acid Donor: This component releases an acid catalyst when heated, initiating the intumescence process.

- Carbonific: This ingredient, often a polyol, provides the carbon source for the char formation.

- Spumific: This component releases gases when heated, causing the coating to expand.

- Pigments and Additives: These ingredients provide color, improve flow, and enhance the coating’s performance.

When exposed to heat, the acid donor releases an acid that reacts with the carbonific, producing a carbonaceous char. Simultaneously, the spumific releases gases, causing the coating to swell and form a thick, cellular char layer. This char acts as a thermal barrier, slowing down the heat transfer to the steel substrate and maintaining its temperature below the critical threshold.

Application and Performance: Ensuring Optimal Protection

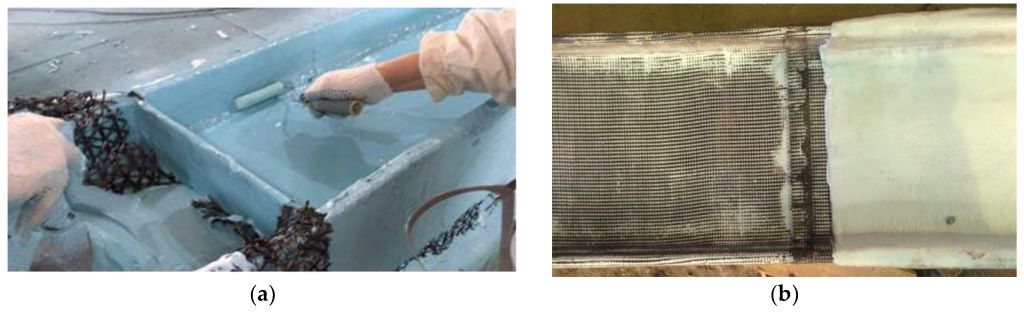

The effectiveness of fire protection coatings depends heavily on proper application and adherence to manufacturer specifications. Key factors influencing performance include:

- Surface Preparation: Thorough surface preparation is essential for optimal adhesion and performance. Steel surfaces must be cleaned, degreased, and primed to ensure proper bonding.

- Coating Thickness: The required coating thickness is determined by the desired fire resistance rating and the specific steel profile. Thicker coatings provide longer fire protection.

- Application Method: Coatings can be applied by spraying, brushing, or rolling. Spray application is typically preferred for large areas and complex shapes.

- Environmental Conditions: Temperature and humidity during application and curing can affect the coating’s performance.

Testing and Certification: Guaranteeing Reliability

Fire protection coatings are rigorously tested to ensure their performance and reliability. Standard fire resistance tests, such as those specified by UL (Underwriters Laboratories) and ASTM (American Society for Testing and Materials), evaluate the coating’s ability to protect steel from fire for a specified period. These tests involve exposing coated steel samples to controlled fire conditions and monitoring their temperature and structural integrity. Certification from reputable organizations provides assurance of the coating’s quality and performance.

Maintenance and Inspection: Preserving Protection Over Time

Like any protective coating, fire protection coatings require regular maintenance and inspection to ensure their continued effectiveness. Factors such as environmental exposure, mechanical damage, and aging can affect the coating’s integrity. Regular inspections should be conducted to identify any signs of damage, such as cracking, peeling, or delamination. Damaged coatings should be repaired or recoated promptly to maintain the required fire resistance.

People Also Ask (FAQs)

Q: How long does fire protection coating last?

A: The lifespan of fire protection coatings depends on various factors, including the type of coating, environmental conditions, and maintenance practices. Generally, epoxy-based coatings can last for 20 years or more with proper maintenance, while water-based coatings may have a shorter lifespan. Regular inspections and timely repairs can extend the coating’s service life.

Q: Can fire protection coatings be applied to existing steel structures?

A: Yes, fire protection coatings can be applied to existing steel structures. However, proper surface preparation is crucial to ensure optimal adhesion. This may involve removing existing coatings, cleaning the steel surface, and applying a suitable primer.

Q: Are fire protection coatings expensive?

A: The cost of fire protection coatings varies depending on the type of coating, the required thickness, and the application method. While the initial cost may seem significant, it’s essential to consider the long-term benefits of protecting steel structures from fire damage.

Q: Do fire protection coatings affect the appearance of steel structures?

A: Fire protection coatings are available in various colors and finishes, allowing for customization to match the aesthetic requirements of the building. Some coatings can even be top-coated with decorative paints for a more refined appearance.

Q: What is the difference between fireproofing and fire protection coating?

A: While often used interchangeably, fireproofing generally refers to thicker, more robust systems like cementitious coatings, while fire protection coating refers to thinner intumescent coatings. In practice, the terms are very close in meaning.

Conclusion: Investing in Safety, Building Resilience

Fire protection coatings are indispensable for safeguarding steel structures from the devastating effects of fire. By delaying the onset of critical temperature, these coatings provide valuable time for evacuation and firefighting efforts, ultimately saving lives and minimizing property damage. Selecting the right coating, ensuring proper application, and conducting regular maintenance are essential for maximizing the effectiveness of fire protection systems. In a world where safety and resilience are paramount, investing in fire protection coatings is not just a regulatory requirement; it’s a testament to our commitment to building a safer and more secure future. As technologies advance, we can expect to see even more innovative and effective fire protection solutions emerge, further enhancing the safety of steel structures for generations to come.

Read More: Understanding Fire and Explosion Hazards in Industrial Settings